rotating bending|Rotating Bending Test : wholesalers Rotating Bending: The wheel spins while attached to a moment arm. Eccentric Mass: The wheel is stationary but an eccentric mass spins internally, creating a moment which allows the eccentric mass cornering fatigue to complete more than twice the amount of cycles in the same time as the rotating bending machine.

Educação a Distância Senar. Nosso portal de Educação a Di.

{plog:ftitle_list}

8 de nov. de 2023 · A Dark Reminder and Call to Action. The Infamous “ quieres agua full video ” video, with its haunting and grim depiction, stands as a sad reminder of Mexico’s .

Rotating-bending test method is an appropriate technique for collecting strain-based fatigue data for wire specimens under zero mean strain conditions (i.e. fully reversed loading, Rε= −1). Testing apparatus is generally comprised of a variable-speed motor and a sensor for counting the .

A rotating bending fatigue testing machine was developed by keeping in mind the basic concepts of technical theory of bending of elastic beams. Different specimens of 6mm to 8mm diameter of . Nicknamed the Rotatamatron 3000, this custom built machine is capable of applying a constant stress across a 2.75" reduced section diameter with a maximum lo. Considering that the current low-stress cropping method for large-diameter metal bar has the disadvantages of large cutting force and drastic change of loading force, a new low-stress cropping method is proposed based on the co-induced crack initiation by rotating-bending and slotting. Based on the strength theory and fatigue damage theory, the dynamic bending .

The rotating bending test is a fatigue test that allows to evaluate the resistance of the wheel exploiting a rotating bending moment obtained through a rotating unbalanced mass. This test reproduces a load condition to which the wheel is subject to when in use. In particular, during this test, the main stresses are developed in the central part .Rotating Bending: The wheel spins while attached to a moment arm. Eccentric Mass: The wheel is stationary but an eccentric mass spins internally, creating a moment which allows the eccentric mass cornering fatigue to complete more than twice the amount of cycles in the same time as the rotating bending machine. In this work, the rotating bending fatigue test was carried out on the laser direct energy deposited (L-DED) titanium alloy to simulate the service condition of the rotating blade, and the laser shock peening (LSP) post-processing was adopted to enhance the fatigue performance. The results showed that LSP induced gradient layer and phase .This document specifies the method for rotating bar bending fatigue testing of metallic materials. The tests are conducted at room temperature or elevated temperature in air, the specimen being rotated.

Two axles were mounted to both ends of the rotating spindle and bending forces were applied to the axles thru a spring mechanism located at both ends of the machine. Between 1852 and 1870, the first systematic fatigue tests were carried out on specifically designed laboratory specimens by Wöhler. These tests enabled Wöhler to relate his . Although rotary bend wire fatigue is a relatively common test, the speed used to perform testing can vary greatly. Given that in vivo loading occurs at a much slower rate than the maximum speed of motors used in wire fatigue testers (e.g., approximately 72 beats per minute for cardiac loading versus 25,000 or more revolutions per minute (RPM) for a high-speed . Rotating bending fatigue (RBF) is the most effective method to simulate the alternating load on rotating blades, so it is often used for fatigue performance testing in the laboratory [9], [10]. Laser shock peening (LSP) is an attractive surface modification technology [11], .

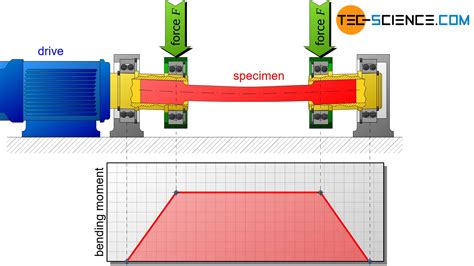

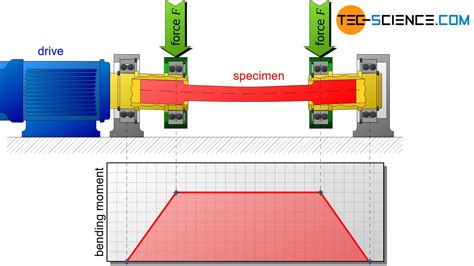

To meet test needs of various applications, Fatigue Dynamics offers rotating beam test machines in bending moment capacities ranging from 60 in.-lb. to 1500 in.-lb. Optional accessories include a high temperature furnace (up to 1800°F), furnace temperature controller, and .What is Raagen & What We Do? Raagen Materials Testing Machines is taking firm steps forward to become a leading and world-class brand in materials testing sector by offering affordable solutions to manufacturers in many sectors with advanced technology and high quality machine system designs for material testing. The rotating bending low-stress cropping machine is a low-stress circumferential fatigue cropping machine based on hydraulic compensation, which is mainly composed of variable frequency motor, hydraulic transmission system, double slider mechanism, cropping mold, movable clamping mechanism and frame. The working principle is that one end of the .testing. The "Rotating Bending Testing Machine" is similar to the original railroad axle-type Wohler used where the bending moment is constant along the beam length. Each point on the Surface of the Rotating Bend Specimen is subjected to fully-reversed cycling (σm = 0) and the tests are generally Constant Amplitude.

This paper presents the design and development of a fast rotating bending test machine f or high-cycle fatigue . tests, which can rotate up to 18,000 rpm, generating cyclic s tresses at 300 Hz.

Rotating bending fatigue tests were conducted at room temperature on a PQ1-6 type rotating bending fatigue test machine, with the cyclic speed of 5000 rpm and stress ratio R = −1. As shown in Fig. 6, electromotor drives specimens rotating through belt and shaft. Experimental stress, coming from weights, was applied to specimens through lever .This paper focuses on explore a novel solving method for bending-bending coupled forced vibrations of a rotating wind turbine blade based on the classical Green's function method, which is well known for solving linear ordinary differential equation with constant coefficients.E2948-24 Standard Test Method for Conducting Rotating Bending Fatigue Tests of Solid Round Fine Wire . E3098-24 Standard Test Method for Uniaxial Pre-strain and Thermal Free Recovery of Shape Memory Alloys . E2368-24 Standard Practice for Strain Controlled Thermomechanical Fatigue Testing . Fracture Mechanics

Rotating bending test

A large-scale fatigue testing machine based on the rotating beam method in a four-point bending configuration was designed and built. With the device, high-strength metal specimens with a 32-mm gauge diameter and a 100-mm gauge length can be tested at a cyclic frequency of up to 48 Hz. In this work, particular attention was paid to evaluating the spatial .This document specifies the method for rotating bar bending fatigue testing of metallic materials. The tests are conducted at room temperature or elevated temperature in air, the specimen being rotated.

A rotating bending fatigue testing machine was developed by keeping in mind the basic concepts of technical theory of bending of elastic beams. Different specimens of 6mm to 8mm diameter of different materials were tested under various loads to analyse the performance of this machine. The experimental readings and theoretical calculations .

In view of the limitations of the existing straightening processes, this paper proposes a rotating bending straightening process. The two ends of the workpiece are clamped by the fixtures, and the .ROTATING FATIGUE MACHINE. This machine demonstrates the fatigue failure of materials when subject to alternating stresses. Based on Wöhler’s design, it uses a motor to rotate a circular cantilever specimen with a load at its free end. It is in two parts: a robust main unit, and a separate control and instrumentation unit. Fig. 7, shows the comparison between fatigue crack growth rate under rotating bending and fatigue crack growth rate determined by NASA/FLAGRO equations (6), (7) for R = −1. Here, the full stress intensity factor range ΔK for rotating bending conditions was used for comparison with results from database equations. It is clear that a lower .

Shear and moment diagram for a simply supported beam with a concentrated load at mid-span.. In solid mechanics, a bending moment is the reaction induced in a structural element when an external force or moment is applied to the element, causing the element to bend. [1] [2] The most common or simplest structural element subjected to bending moments is the beam. A rotating bending fatigue testing machine was developed by keeping in mind the basic concepts of technical theory of bending of elastic beams. Different specimens of 6mm to 8mm diameter of .Flexion and Extension. Flexion and extension are movements that take place within the sagittal plane and involve anterior or posterior movements of the body or limbs.For the vertebral column, flexion (anterior flexion) is an anterior (forward) bending of the neck or body, while extension involves a posterior-directed motion, such as straightening from a flexed position or bending .

Rotating Bending Test

aggregate impact value test video download

aggregate impact value test wikipedia

Experimental Study on Rotating Bending Fatigue Behavior

Resultado da Descrição. Mais completa e atualizada de acordo com a legislação do Código de Trânsito Brasileiro e últimas resoluções do CONTRAN. Mais de 700 .

rotating bending|Rotating Bending Test